What is the Core System?

The original Core System was introduced in 2003 by 50/50. Traditional UFS frames are a single piece design, typically made out of an injection filled nylon or machined aluminum. The Core System pairs these two materials to make a single frame with limitless potential.

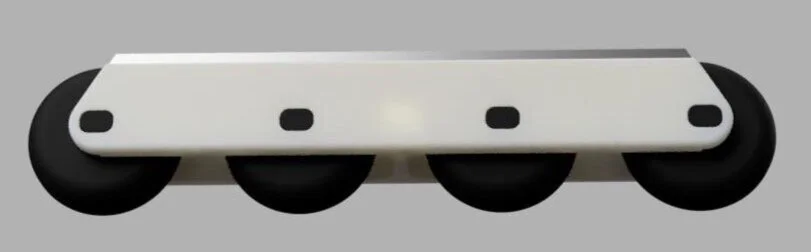

At the heart of the Core System is an extruded aluminum Core. The Core attaches to the boot using the two bolt UFS system. The frame walls then attach to the Core using the frame spacers and get sandwiched securely into place with the wheel axles.

The walls can be made of a variety of materials; Glass Filled Nylon, UHMW, PLA+, you name it. Because the Core takes all the abuse, the walls only need to provide the optimal design for skating and grinding.

Only two wall designs were released for the original Core System. Now with the advances in 3D printing we are introducing the new Core System 2 and sharing the design with the community. Designers can download 3D models to create their own custom frame walls, and print them using off the shelf equipment. Your dream frame design can now be a reality.

Developer Resources

We want to help you develop for the Core System. We’ve done a lot of work putting together all the information you might need, but of course there’s going to be things missing. This page will be updated as we learn more about the system and as developers push it to the limits.

Printing Tips and Tricks

So you’ve got your design and you’re ready to print, but you don’t know where to start? Here’s a few lessons we’ve learned from printing parts.

There are lots of great printers on the market, but we recommend the Creality CR-10 for its ease of use and solid performance. The print bed is 300x300x400, which is more than enough room for printing a Large frame wall diagonally. You can usually find them for less than $400 on Amazon. You don’t need the latest and greatest, the CR-10 is a workhorse and offers more than enough for what we need.

Fusion 360 is the software of choice for most hobbyists, and Cura is great for preparing your STL file for your printer. The Core Developer Kit includes Fusion360 files you can use to quickly get started with your design.

We’ve tested a bunch of different filaments, but the best performing material for the price we’ve found is PLA+. Not only is it cheap (around $20-$25 for 1000g), but PLA+ is compostable! We recommend the eSun brand based on available colors and consistency with prints. When printing PLA+, we’ve found that 215F is the ideal temperature for most colors. This temperature can be changed in Cura or whatever slicing software you use.

Frame walls should be printed at 100% infill to be skateable, but for fitting tests we typically print at 20%. They’ll still work just fine for skating to test rockers and grooves, but won’t last very long and may crack unexpectedly.

Frame Wall Design

There’s never been a playground like this for designing frames. We’re sure you’ve skated long enough to know what you like and what works well for your style. Find yourself a fresh set of your favorite frames, grab a set of calipers, and start measuring. You’ll learn fast what numbers are important and where you can experiment.

The Core will handle all of the stress, but make sure you give it some help. We make sure the axle recess has at least 2mm of frame wall material where mounting to the Core. 3mm would be ideal, but no need to overdue it. Even with a small crack at the axle, the frames will still be skateable.

Be opinionated! This isn’t the time to offer rocker options. Your walls should skate the way you intend them to skate. If you want a 1mm rocker, build it into the wheelbase. If you want wheelbase protection optimized for 58mm wheels, go for it. Don’t leave any room for confusion. You know what your optimal setup is. Make it perfect!

The Core System supports 65mm wheels flat, but if you have the right soul plates you can fit 72mm wheels. You’ll need 3.5mm of clearance, which most soul plates don’t have. It’s a really simple modification to consider, though not all skaters will want to do it.

Core Frame Market

Our goal with the Core Frame Market is to make it easier for developers to share their frame walls with the community, and for skaters to easily support developers and try new frame designs. This sort of thing has never been attempted in the industry before, so please be patient with us as we figure out what works. We plan to continue to grow our printer network and deliver frames as quickly as possible, and appreciate your understanding.

Since the concept of a frame wall market is new to everyone, we’re staying focused on making the experience smooth for customers. Initially, frame wall pricing will be fixed at $50/set to reduce confusion. At launch we limited the color options to black and white, and now yellow. This will make it easier for us to manage resources. More color options will be available in the future.

The $50 frame wall pricing breaks down as follows: $10 for the developer, $35 for the person doing the printing/materials/electricity/fulfillment, and $5 for the Market. These numbers might change in the future as we learn more about what customers want and expect, but believe this pricing allows for everyone involved with the purchase to make a decent amount of money for their effort.

We want to make sure that all developers have a chance to sell their frame walls. So we’re limiting each developer to two (2) wall designs on the Market. This is to avoid developers spamming the store with dozens of frame variations. We recommend choosing your most unique and best performing designs, and continually improving them based on customer feedback. Remember, you can print and sell as many frame designs as you want yourself, but only two designs per developer on the Market.

We all love the classic frame designs, but we take intellectual property seriously. Your designs need to be your design, not a tribute to someone else’s design. It’s going to be difficult to say how close a design can be, but we’ll know it when we see it. If your design is flagged as too similar to an existing frame, we’ll ask you to change it before removing it from the Market. We don’t want frame companies looking for lawsuits, please respect people’s work.

Weird frames are fun to see, but they should be equally fun to ride. Make sure your design is skateable and not just an art exhibit. You must test your design before submitting to the market to make sure it works as expected, and send us a video along with your submission for proof. Skaters need to have confidence that purchasing a frame wall will not be a waste of their money.

Breakages happen. As we all know, skating is tough on equipment. If we get complaints from customers that your design is breaking faster than expected, we’ll ask you to improve it. We want skaters to feel like they’re getting their money’s worth. Again, this is a tough one to describe. An example could be a freestyle frame where the groove is so thin it wears through after a session. Nobody wants a bad experience.

All of these ideas are subject to change as the Market evolves, so take them more as guidelines than strict rules. We want this to be a way for skaters to try new things, and for developers to share their ideas. With that in mind, we’ll continue to tweak things when we see room for improvement, and appreciate any feedback you might have to make this better for everyone.

Submit Your Design

Are you ready to sell your walls in our shop? Let us know so we can get you set up.